eABS-CF

eABS-CF is eSUN’s latest high-performance 3D printing filament that combines the trusted mechanical properties of ABS with the enhanced rigidity of carbon fiber reinforcement. Tailored for professional users, engineers, and makers, eABS-CF is ideal for durable, lightweight, and visually refined prototypes and end-use components.

Product Features

Features

- Significantly Improved Rigidity and Strength

- Enhanced Temperature and Chemical Resistance

- Lightweight and High Strength-to-Weight Ratio

- Matte Finish with Rich Color Options

- Excellent Dimensional Accuracy and Low Warping

- Versatile Application Range

Shipping Weight

- 1.400 Kg

Description

eSUN eABS-CF – Carbon Fiber Reinforced ABS Filament

Performance Elevated. Functionality Redefined.

ABS has long been a popular choice in industrial and engineering-grade 3D printing due to its toughness, heat resistance, and processability. eSUN has taken this trusted material to the next level with eABS-CF—an advanced carbon fiber-infused ABS filament that significantly improves rigidity, flexural strength, and thermal resistance.

With a flexural modulus of 2694 MPa (an 82% increase) and flexural strength of 76 MPa (a 65% improvement over standard ABS), eABS-CF is purpose-built for demanding use cases like tooling, fixtures, electronic components, automotive prototyping, and lightweight structural parts.

Key Features

Significantly Improved Rigidity and Strength

eABS-CF is formulated by reinforcing traditional ABS with a high content of chopped carbon fibers. This enhancement results in a remarkable increase in structural integrity and stiffness. Test results show that the flexural modulus reaches 2694 MPa—an 82% improvement over standard ABS—while the flexural strength increases by 65%, reaching 76 MPa. These upgrades make it highly suitable for parts that must endure stress, strain, or repeated mechanical loads.

Enhanced Temperature and Chemical Resistance

Thanks to the robust properties of ABS and the stability provided by carbon fiber, eABS-CF exhibits improved thermal performance, with better resistance to heat deformation. This allows printed components to perform reliably even in high-temperature environments. Additionally, the material is more resistant to exposure from chemicals, acids, and alkalis, making it ideal for industrial, automotive, and outdoor applications where chemical exposure is a concern.

Lightweight and High Strength-to-Weight Ratio

Despite its rigidity, eABS-CF maintains a low material density due to the carbon fiber content. This makes it ideal for applications where reducing weight without compromising strength is critical—such as in drone frames, RC vehicles, and aircraft models. Lighter prints also mean reduced material usage and faster print times without sacrificing performance.

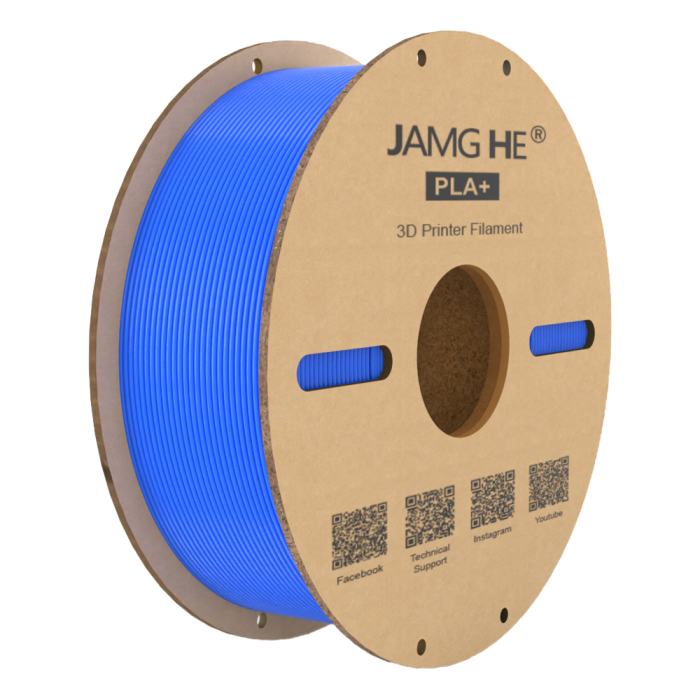

Matte Finish with Rich Color Options

Unlike most carbon fiber filaments that are limited to black, eABS-CF offers a visually striking matte surface texture with a range of deep, premium color options including black, dark red, dark blue, dark purple, and dark green. This makes it ideal for applications where visual appeal matters alongside mechanical function, such as consumer product housings or demo-ready prototypes.

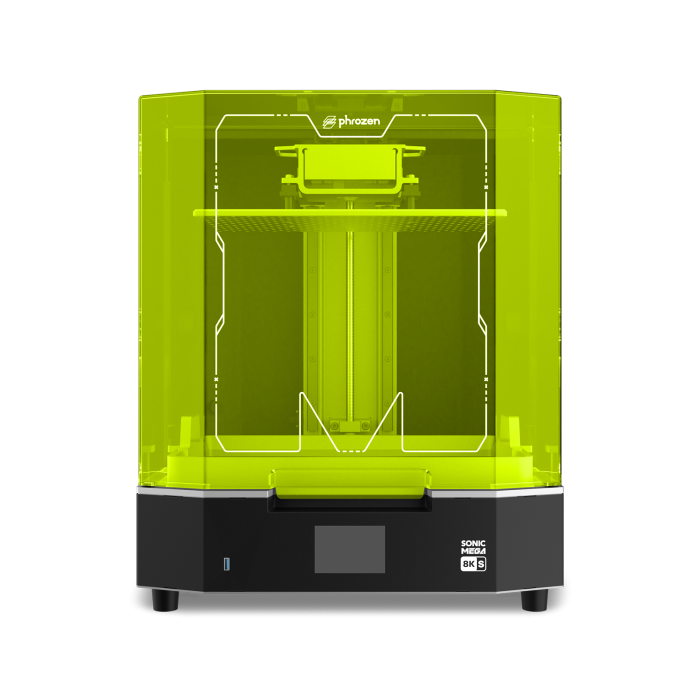

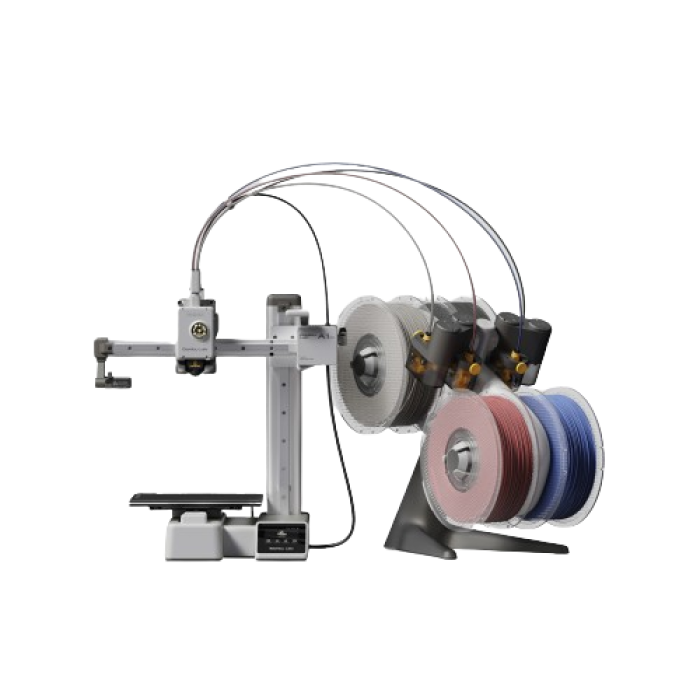

Excellent Dimensional Accuracy and Low Warping

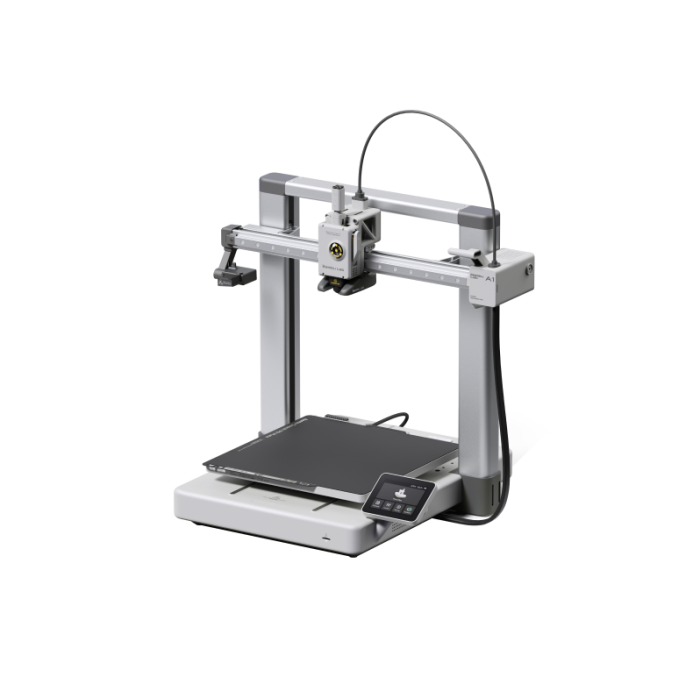

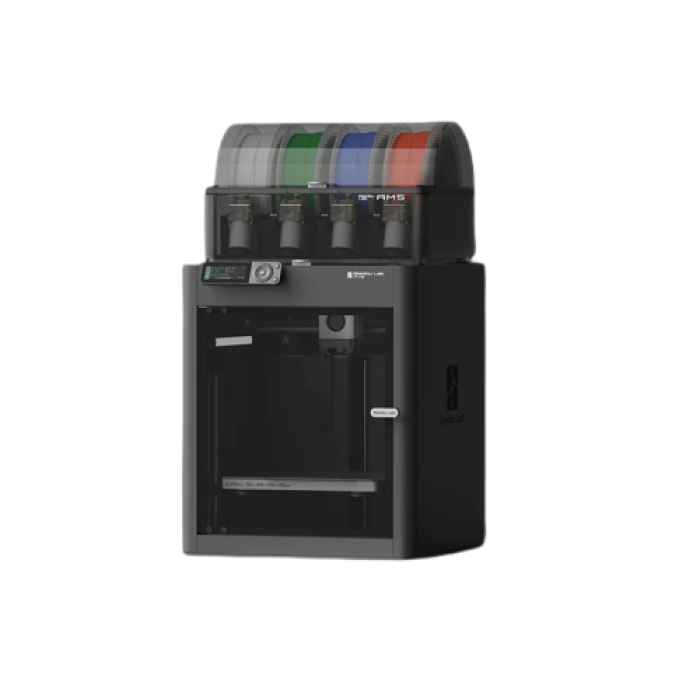

The addition of carbon fibers helps to stabilize the ABS matrix during printing, reducing warping and improving dimensional accuracy. This makes eABS-CF easier to print than traditional ABS, especially for larger models or parts with complex geometries. However, it’s still recommended to use an enclosed printer to manage the natural shrinkage behavior of ABS-based materials.

Versatile Application Range

Engineered for functionality, durability, and aesthetics, eABS-CF serves a wide range of industries and purposes. It is perfect for printing tools, jigs, enclosures, engineering-grade components, and structural parts that demand strength, heat resistance, and a professional finish.

Specification

Parameter Information

-3.png)

-14.png)

-1.png)

-8.png)

-2.png)

-2.png)

-1.png)

-1.png)

- For X1 Series-1.png)

- For AMS inside.png)

-4.jpg)

-4.png)

-4.png)

-3.png)

.png)

.png)

.png)

.png)